Go from confusion and chaos to feeling crystal clear about the state of your business in just 2 days.

Have you ever wondered how to actually get to the root of your problems in your business?

Or that you are constantly making processes but they don’t actually work?

In this 2 day workshop, we’ll break down the current state of your business and give you a 100% accurate state of affairs so that you can confidently solve problems and create processes that work.

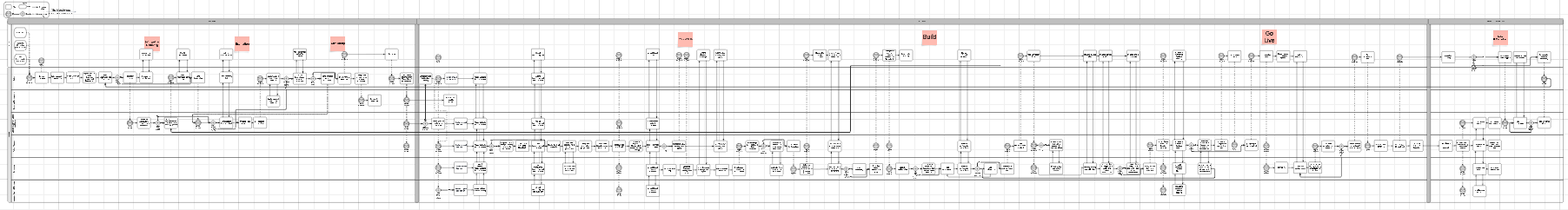

Most methods of process mapping aren’t necessary and are over-complicated and siloed.

Plus, everyone thinks process mapping is the SAME. But this is what they get it wrong. There are many nuanced methods for doing process mapping effectively.

This is where the goods and information flow comes in because it’s the one that works.

I honestly don’t know why it’s not taught more considering it’s THE tool that Toyota uses for everything.

Not to mention it’s the first step of every process improvement so you quite literally can’t do process improvement without it.

Inconsistency in your processes is actually what is contributing to the breakdown.

With this 2-day virtual workshop, you will get crystal clear on the current state of your business so that you have a very strong foundation to solve problems.

And the best part is you don’t need to start anything new or disrupt anything.

Contrary to popular belief, process isn’t only for manufacturing. This offer is for service-based businesses. Plus it’s common to think that process is going to take away your uniqueness.

But I promise it’s actually what helps you stand out MORE.

During this 2-day workshop, we will:

- Understand the current state of your business with 100% accuracy

- Get all of your departments on the same page and excited about moving toward the future

- Stop assuming what is happening in your process and get crystal clear with visualizations

- And feel total peace of mind and safety when you get rid of the chaos in your day to day

- Plus a finished flow that is so good you’ll want to show everyone!

The Flowstate Workshop

This is for you if you’re:

- Tired of feeling confused about what is going wrong in your daily operation

- Feel as if your departments don’t communicate well with one another

- Frustrated with making assumptions but not having real data to rely on when making decisions

- Feeling chaotic in your day to day and can tell that your team is too

- Wanting a completed process map of your business

*Must be a service-based business to apply

We are no longer reacting to change.

“We were known for our strong core processes but with significant growth we outgrew them. Hilary helped us find our way back to strong processes that drive revenue for our customers. We are no longer reacting to change, we’re leading change.”

– JIM TASZAREK, CEO of Market Enginuity

I have confidence in scaling.

“Our business grew very quickly in the past few years, and some of our processes did not keep up. Hilary helped us narrow in on a path for sustainable improvement involving our team in a way that led to improvement in process and an even better experience for our employees and customers. I have confidence in our ability to scale and fulfill our brand promise for more customers.“

– HARRY CLARK, CEO of Soundrise

Hi! I’m Hilary

I help CEOs master PROCESS so they can scale without losing their soul and sanity.

You deserve to scale your business so that you can provide thriving opportunities for your people in the way you’ve always dreamed of. I’m here to help you make that happen.

Over time, I’ve also been able to layer my own learnings and expertise from my background at Toyota Motor Asia Pacific to create a methodology that makes some of the most complex process improvement principles simple. It’s not just the largest companies around the world that deserve effective processes. I’m making that strategy accessible to you.

FREQUENTLY ASKED QUESTIONS

The two-day workshop can be conducted either back-to-back or on two separate days, but we strongly recommend completing both days within two weeks. Some examples of what other companies have done include conducting one day on a Friday and then the next day on the following Friday, or any other day of the week that aligns with your standard operating procedures. Another example is meeting on a Wednesday and then the following Thursday. Any combination of these can work, but it’s best to match the days of the week to when your teams have the most open space to engage in deep work.

Following the PDCA process, the approach begins with understanding the current state through the Goods and Information Flow. Therefore, the goal of the two-day workshop is to create your company’s goods and information flow, referred to as Your Company Way.

By the end of the two-day workshop, your team will have alignment on:

- Where the processes are not being followed cross-functionally

- Of those, which are the fastest, easiest, and cheapest to solve

- An action plan for the top problems to solve without changing anything or adding anything new

- A plan for how to retrain these processes and who will own them

Therefore, by bridging the gap between the current state and what the operation is supposed to be, you can drive massive results without needing any new ideas.

The most valuable way for clients to engage with me is to take the workshop, retrain on their processes, and then kick off a full cycle of PDCA improvements with my support. Essentially, the workshop is designed for you to launch the activity and self-implement. After you have retrained, if you would like more support with implementation to speed up and improve your results, that’s when teams tend to engage me for 6 months to facilitate through all eight steps of the PDCA process.

In 6 months, we can effectively change on average 30% of the operation and implement 40 to 50 countermeasures across the entire customer experience. This is more of a massive process overhaul. Consider it a quantum leap. The company will not look the same afterward.

This is a weekly cadence for one hour/week with one-hour homework for a team of 6-8 people at $10,000/month. $60,000 for the whole investment.